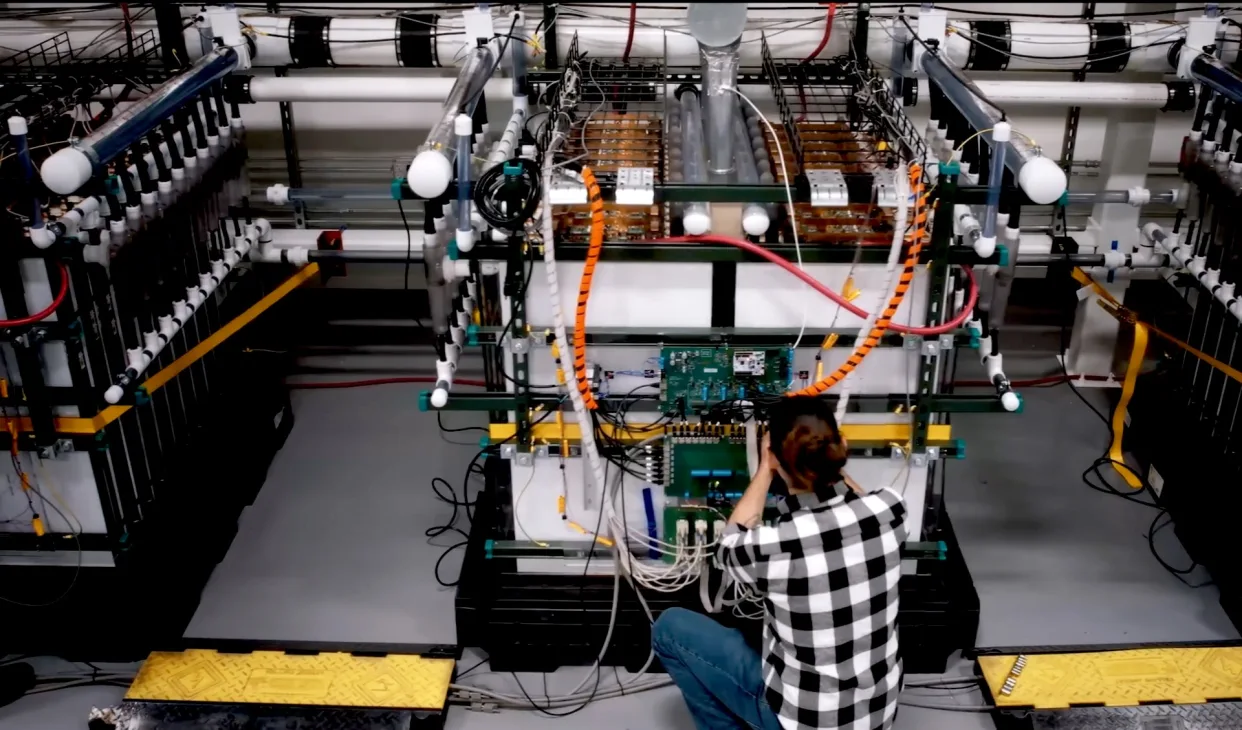

Form Energy, an energy startup based in Massachusetts, has been developing an innovative iron-air battery that uses the oxidation and reduction of iron to store energy.

While working on this battery technology, Form researchers discovered the process could also be used to more cleanly and efficiently produce iron needed for steelmaking.

Traditionally, oxygen must be removed from iron ore through a fossil fuel-intensive high-heat furnace process. Form’s method uses low-temperature electrolysis in an alkaline solution driven by renewable electricity to continuously produce iron powder.

This removes the oxygen from iron ore (changing it from iron oxide to metallic iron) as part of a repeatable process, similar to how the iron-air battery works but on an industrial scale.

It could provide an affordable, scalable and less polluting way to produce iron for steelmaking compared to traditional methods, potentially reducing the industry’s carbon emissions.

Form received $1 million in government funding to further develop this process, which it says could match current production costs while eliminating greenhouse gas emissions. This unexpected discovery could thus help “green” a major global industry.

Source: TCD